Contract measurement

and testing service for

complex components

With one of the largest measuring systems in Europe, we take over the contract measurement and quality assurance of your components – precise, fast and digital. We also reliably measure complex geometries and custom-made products.

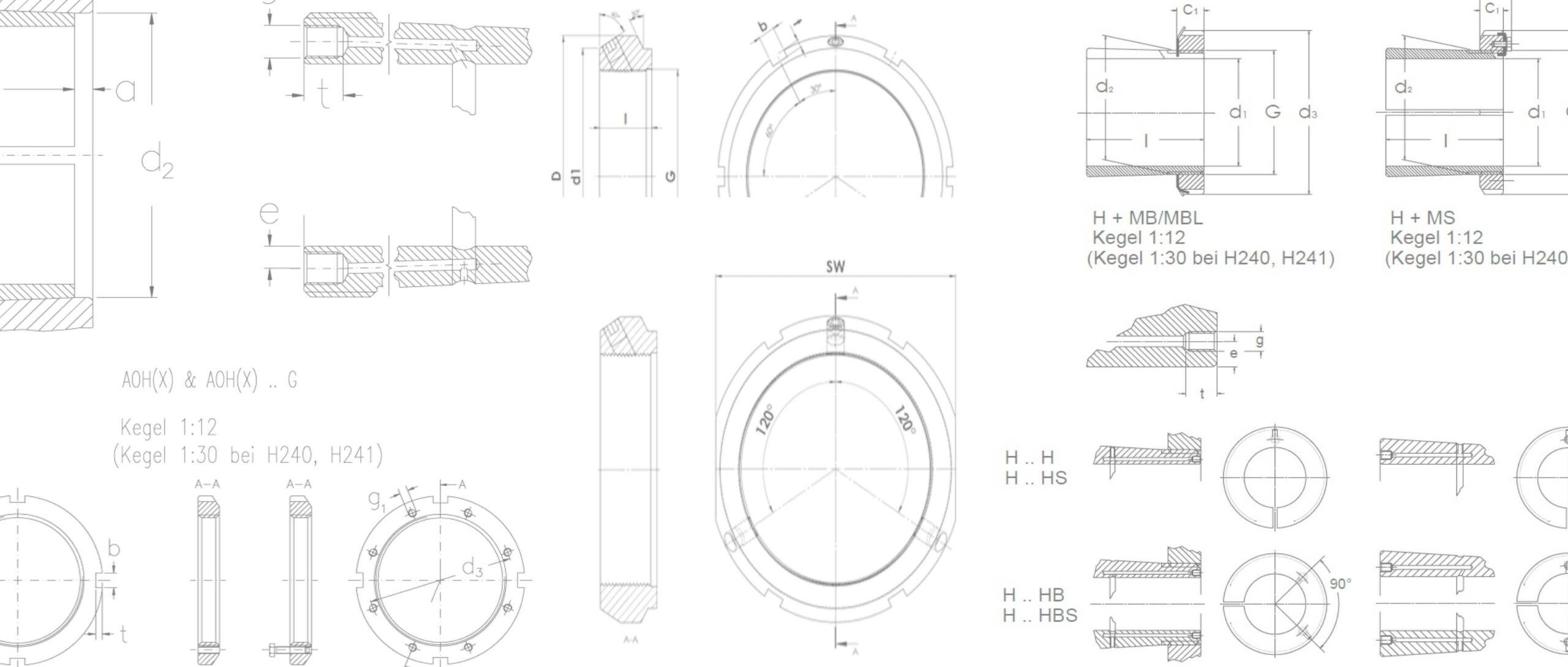

Precise component measurement and contract measurement

Contract measurement and 3D coordinate measurement for large components

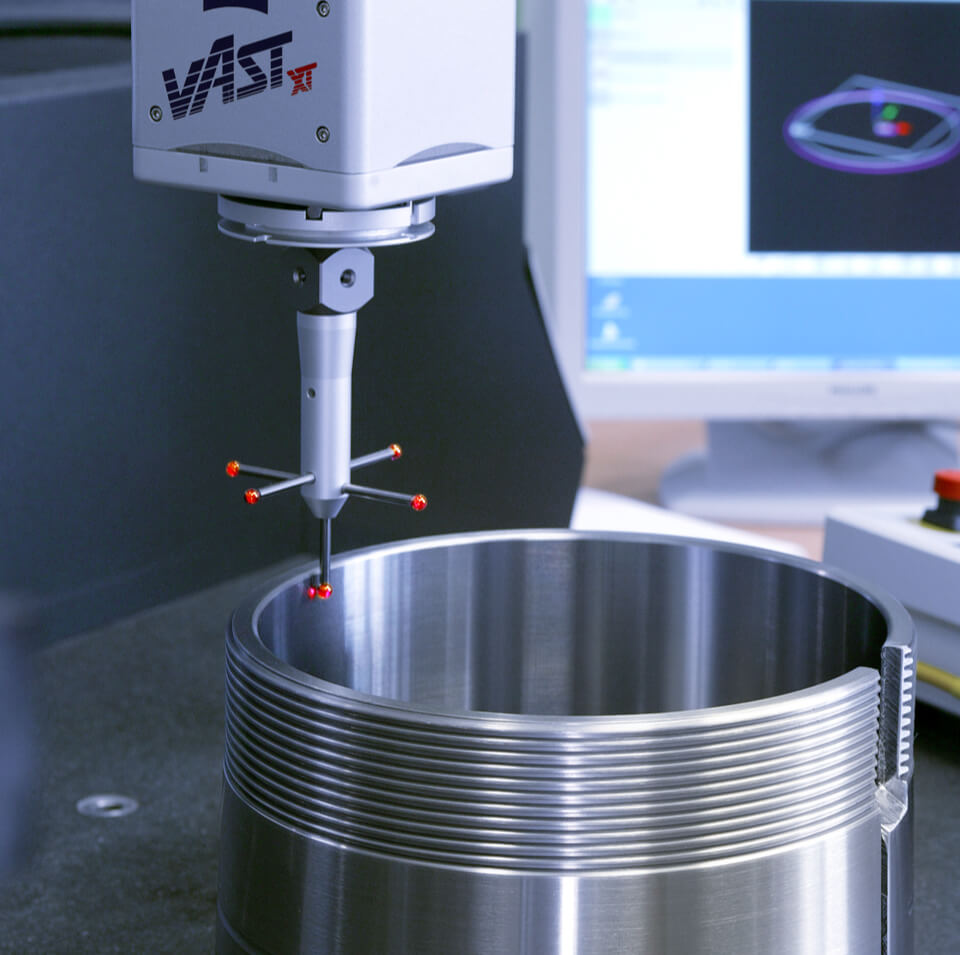

Are you looking for a partner for precise component measurement, even with complex geometries? We take over the contract measurement of your components with state-of-the-art 3D coordinate measurement and laser measurement technology.

Our high-precision coordinate measuring machines are programmable, scanning and stationary. With a measuring range of up to 4000 x 7000 x 3000 mm, we can reliably measure even XXL components.

Whether individual pieces, series or XXL components – with one of the largest measuring systems in Europe, we guarantee the highest precision and reliable results. Our experienced team tests complex geometries, large components and custom-made products – independently, documented and, on request, with meaningful evaluation.

Are you looking for a partner for precise component measurement, even with complex geometries? We take over the contract measurement of your components with state-of-the-art 3D coordinate measurement and laser measurement technology.

Our high-precision coordinate measuring machines are programmable, scanning and stationary. With a measuring range of up to 4000 x 7000 x 3000 mm, we can reliably measure even XXL components.

Whether individual pieces, series or XXL components – with one of the largest measuring systems in Europe, we guarantee the highest precision and reliable results. Our experienced team tests complex geometries, large components and custom-made products – independently, documented and, on request, with meaningful evaluation.

Our service for contract measurement

Initial sample inspection, roughness and contour measurement as well as reverse engineering

With state-of-the-art 3D measurement technology, laser scanning and expertise, HSP offers reliable and series-accompanying contract measurements – from initial sample inspection to reverse engineering. Whether according to DIN ISO or individual customer specifications: We offer high-precision measurement services with digitized test reports and complete traceability. On request, we can also take over the collection and return delivery of your components.

WHY HSP?

Measure precisely, save costs –

Your advantages with HSP contract measurement

Use our state-of-the-art measuring systems for XXL parts and complex geometries without having to invest in expensive technology yourself.

Even the most difficult components and custom-made products are measured to micrometer accuracy according to international standards.

Our 3D measurement technology captures digital data for large and oversized components quickly and reliably.

Benefit from fast, digital measurement reports that provide you with maximum transparency and immediate decision-making bases.

Whether individual parts or series production – we adapt our contract measurement to your requirements and production cycles.

All measurement results are documented with international certificates and serve as a reliable basis for quality controls.

Our experts are always up to date with the latest international measurement standards and ensure exact results.

After the measurement, you can have identical parts manufactured directly at HSP – seamlessly from the measurement process to production.

Early and precise measurement minimizes rework, scrap and production risks, while saving costs.

Experience and competence at the highest level

Competent specialist personnel

& international standards

Our measurement technicians are well trained and are continuously trained on current measurement standards and procedures. This ensures standard-compliant contract measurement that meets all international requirements. This ensures that your measurement orders are implemented professionally and reliably – no matter how demanding your requirements are.

Highest precision – independent and reliable

Contract measurement with laser and scanning technology for large and complex components

Whether prototype or series production, whether simple shape or complex geometry – we take over the contract measurement of your components independently and using the latest technology. Thanks to one of the largest measuring machines in Europe, modern laser and 3D scanner processes and fully digitized processes, we guarantee fast, precise and documented results, even for particularly large

or demanding components. As a technology-independent partner, we are not bound to specific manufacturers or standards. This allows us to remain flexible in implementation and can meet your requirements individually – from individual measurement to series-accompanying quality inspection.

Whether prototype or series production, whether simple shape or complex geometry – we take over the contract measurement of your components independently and using the latest technology. Thanks to one of the largest measuring machines in Europe, modern laser and 3D scanner processes and fully digitized processes, we guarantee fast, precise and documented results, even for particularly large

or demanding components. As a technology-independent partner, we are not bound to specific manufacturers or standards. This allows us to remain flexible in implementation and can meet your requirements individually – from individual measurement to series-accompanying quality inspection.

FAQ about

metrology,

components &

services

Metrology

HSP uses high-precision tactile and optical measurement technology, including 3D coordinate measuring machines, form and contour measuring systems as well as roughness and roundness tests. Through air-conditioned measuring rooms and regular calibration, we guarantee reproducible results in the µ range – even with complex geometries and special materials.

Our certified measurement methods achieve measurement accuracies in the micrometer range. Thanks to CNC-controlled 3D measuring systems and digital documentation, we deliver traceable test reports that meet the high quality requirements of the aviation, energy and mechanical engineering industries.

Components

We measure components from a few millimeters to an outside diameter of over 4,000 mm. Thanks to modular measuring setups, both filigree precision parts and large-dimensioned components can be precisely recorded.

Yes, in particular rolling bearing components, rings, cages and other rotationally symmetrical parts are regularly tested at HSP. Our specialized measuring devices enable high-precision concentricity, coaxiality and flatness measurement.

Yes. With optical 3D scanner technology and CAD comparison analyses, we also capture free-form surfaces, undercuts and irregular contours. This enables a complete digital component evaluation and dimensional inspection according to CAD data record.

Our measuring systems are specialized in metallic materials – from steel to bronze and aluminum to brass. Coated or hardened surfaces can also be precisely measured without damaging the component surface.

Services

Yes. Based on precise 3D measurement data, we reconstruct component geometries and create CAD models for the reproduction or optimization of existing components. This is ideal if no drawing is available or spare parts have to be remanufactured – for example for rolling bearing cages or special components.

Of course. All measurement results are digitally documented and provided as a test report, CAD comparison or initial sample test report (EMPB) – fully traceable and compatible with common quality systems.