Less waste, more

brains – that's smart

manufacturing.

With efficient processes and state-of-the-art technologies, we shorten our customers’ time-to-market, thus permanently strengthening their competitiveness.

INDUSTRY 4.0

Intelligent processes, sustainable results.

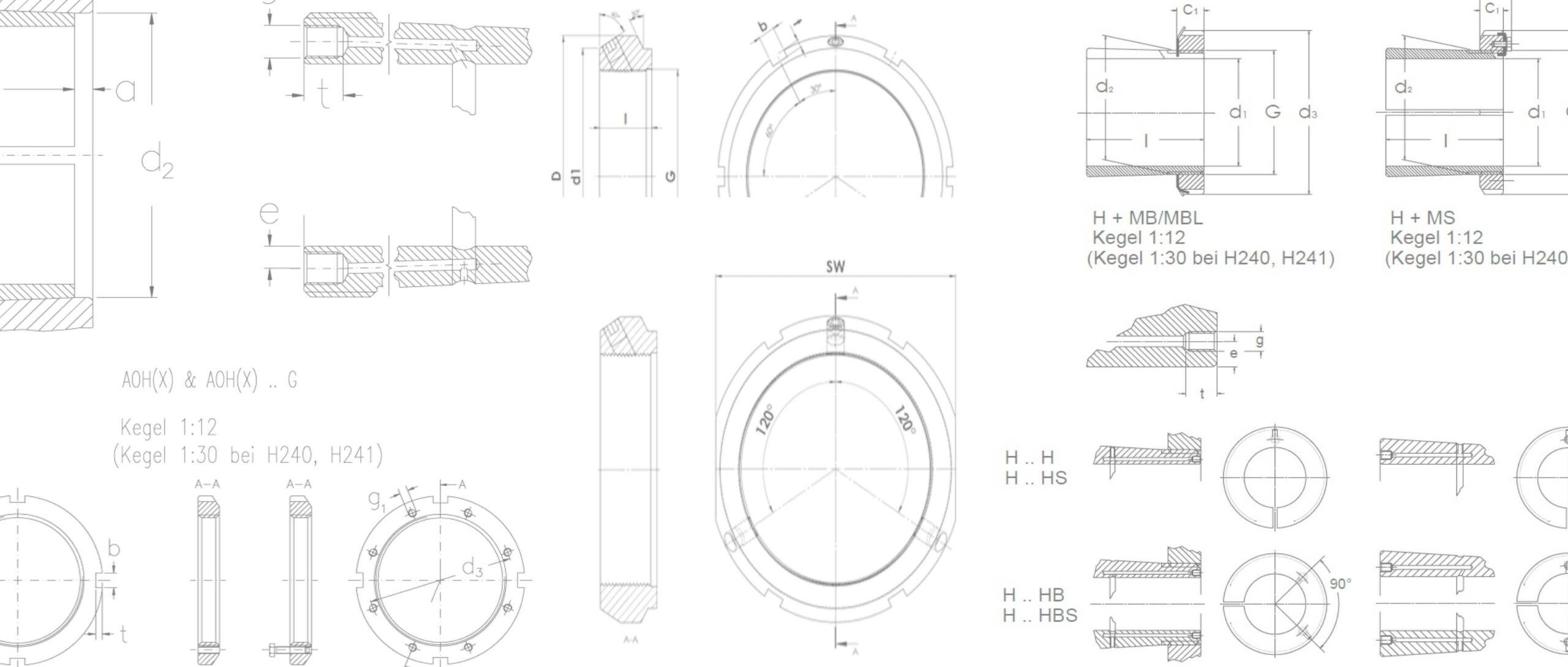

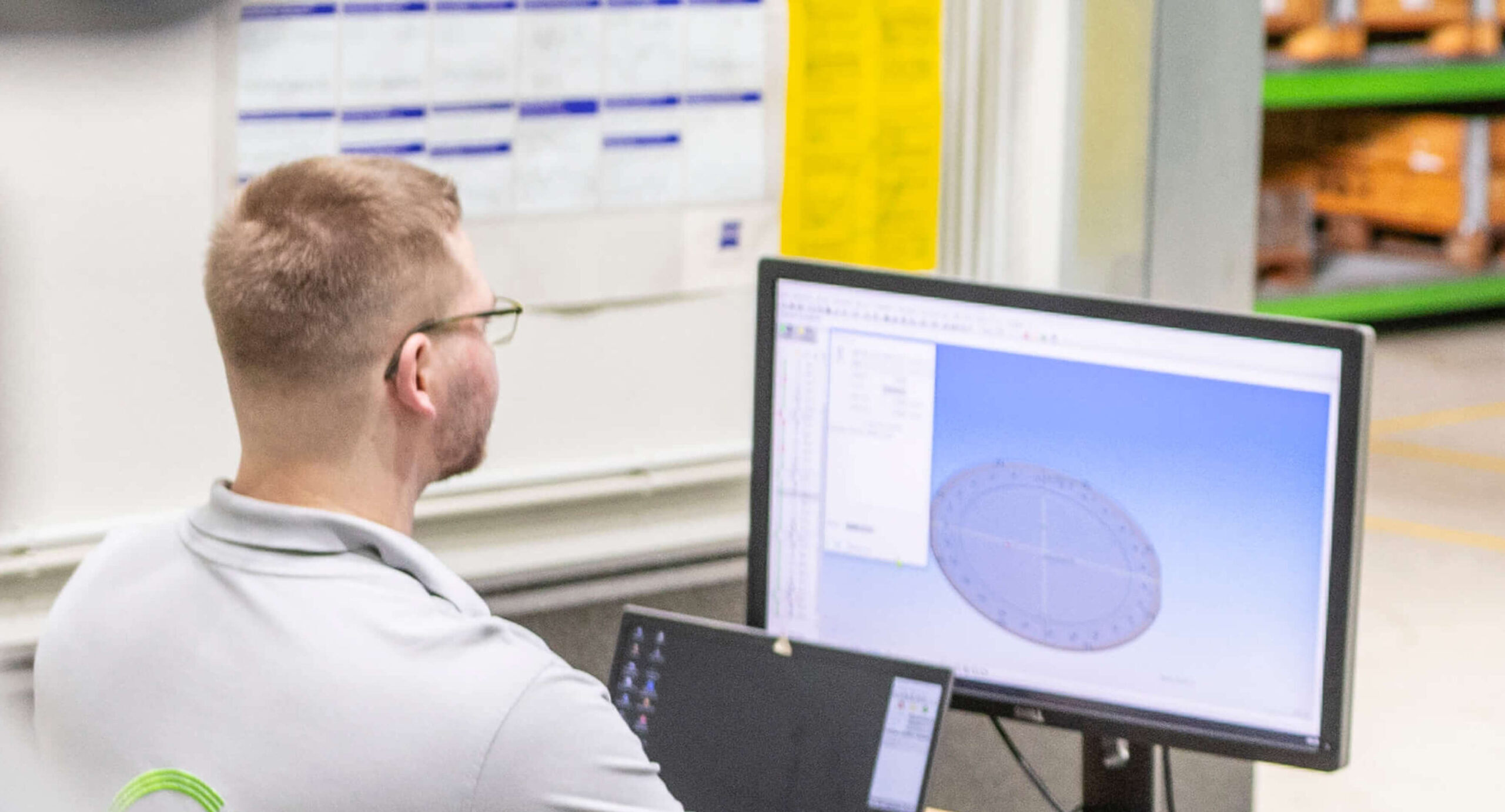

Maximum customer orientation at competitive prices? This is only possible with digital manufacturing and end-to-end Industry 4.0 networking. At HSP, Industry 4.0 means more than pure automation – it gives our

experts the freedom to develop creative solutions that only humans can provide. We network people, machines, and processes paperlessly into an intelligent production system. Automated processes ensure maximum efficiency, transparency, process reliability, traceability, and precision – even for individual requirements from batch size 1. Because smart technology does not replace smart minds – it supports them. Networked. Efficient. Future-proof.

Maximum customer orientation at competitive prices? This is only possible with digital manufacturing and end-to-end Industry 4.0 networking. At HSP, Industry 4.0 means more than pure automation – it gives our

experts the freedom to develop creative solutions that only humans can provide. We network people, machines, and processes paperlessly into an intelligent production system. Automated processes ensure maximum efficiency, transparency, process reliability, traceability, and precision – even for individual requirements from batch size 1. Because smart technology does not replace smart minds – it supports them. Networked. Efficient. Future-proof.

WHY HSP?

Industry 4.0 for more efficiency & sustainable production

End-to-end digital workflows from design to delivery reduce lead times and increase efficiency. This allows precision components to be produced faster and more economically.

Our Industry 4.0 systems make it possible to flexibly mass-produce individual custom-made parts – with consistently high quality and optimized unit costs.

HSP integrates planning, manufacturing, testing, and logistics into digitally networked processes. This creates transparent, stable process chains – all the way to ready-to-install delivery.

Thanks to digital data acquisition in all manufacturing steps, we keep an eye on quality, capacity, and delivery status in real time – for maximum planning reliability.

Automated testing and measuring systems ensure that each series meets the specifications. Digital traceability ensures complete quality control.

Thanks to adaptive manufacturing systems and digital production control, HSP reacts immediately to design changes or shifts in demand – without any loss of quality.