Ready to mount

rolling bearing cages

as custom-made parts

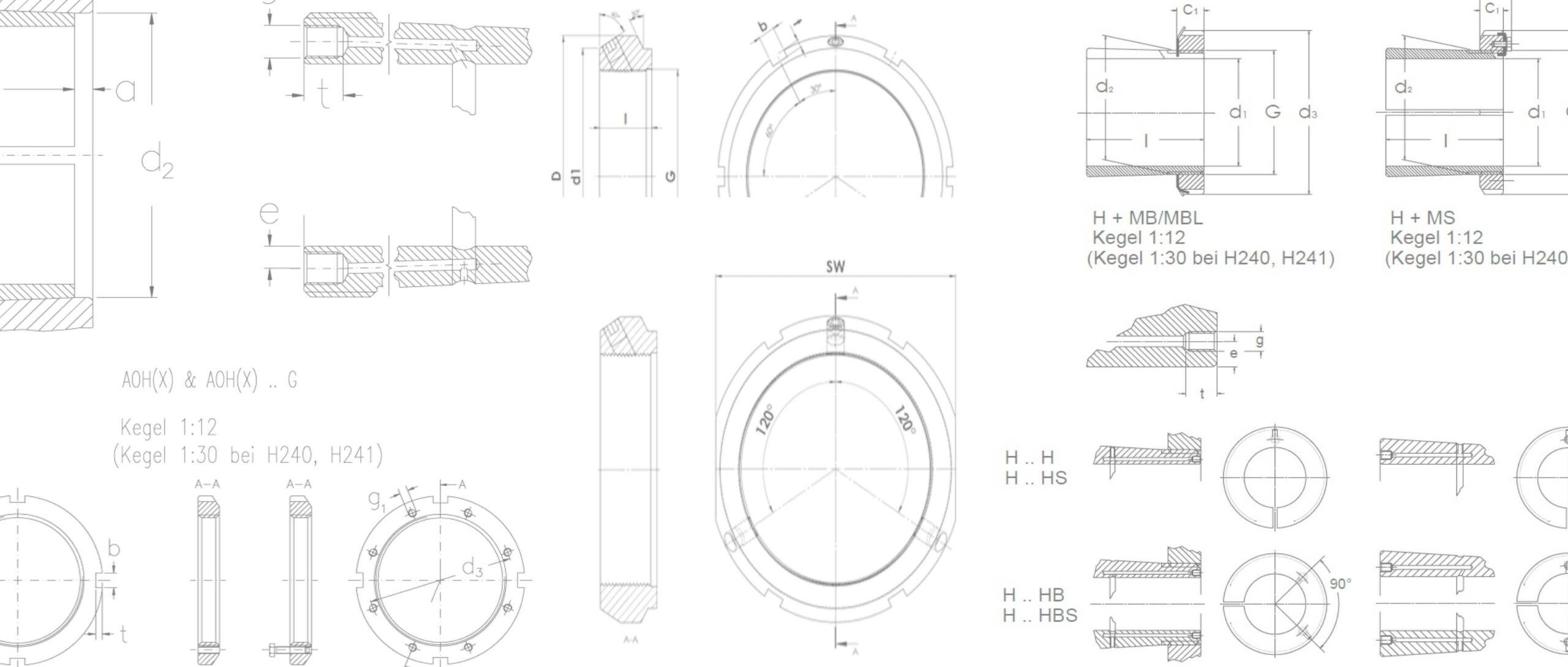

HSP manufactures high-precision rolling bearing cages according to individual drawings from steel, brass, or aluminum, with documented process reliability for series production and special designs.

Custom-Made Parts for the Rolling Bearing Industry

Custom Rolling Bearing Cages for Demanding Applications with Complex Geometries

Whether for tapered roller bearings, cylindrical roller bearings, or special designs – we manufacture rolling bearing cages precisely as custom-made parts and with the highest precision. At HSP, economic manufacturing processes, reliable quality, and absolute dimensional accuracy are paramount. On specialized CNC lathes with

compensating and hybrid chucks and 5-axis centers, precision cages are produced from steel, brass, bronze, or aluminum with outer diameters up to 4,000 mm. For decades a partner to the international rolling bearing industry, we combine technological manufacturing expertise with deep industry knowledge – for individual cage solutions in series or as special designs. This deep industry knowledge is the foundation for our custom-made parts business unit – specializing in demanding components for bearing technology.

Whether for tapered roller bearings, cylindrical roller bearings, or special designs – we manufacture rolling bearing cages precisely as custom-made parts and with the highest precision. At HSP, economic manufacturing processes, reliable quality, and absolute dimensional accuracy are paramount. On specialized CNC lathes with

compensating and hybrid chucks and 5-axis centers, precision cages are produced from steel, brass, bronze, or aluminum with outer diameters up to 4,000 mm. For decades a partner to the international rolling bearing industry, we combine technological manufacturing expertise with deep industry knowledge – for individual cage solutions in series or as special designs. This deep industry knowledge is the foundation for our custom-made parts business unit – specializing in demanding components for bearing technology.

Experts for Extremes

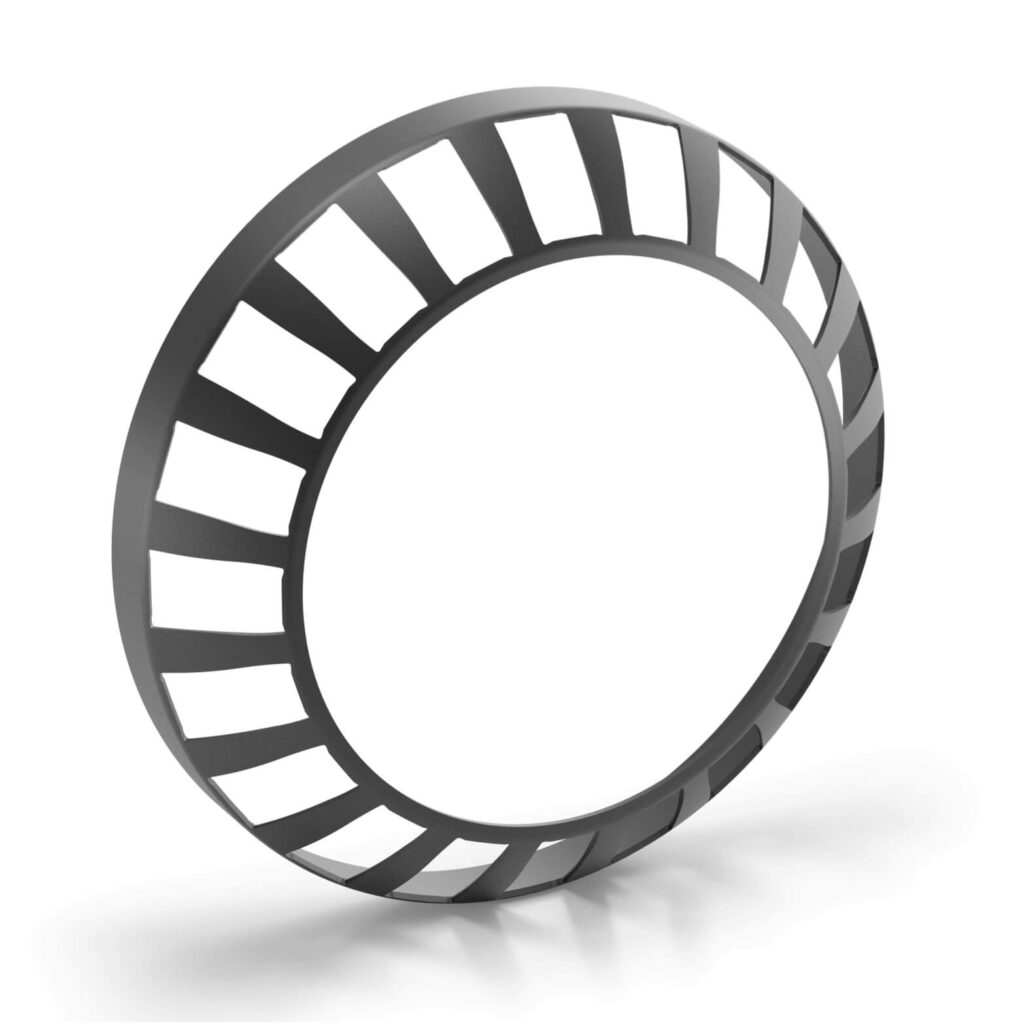

Custom Rolling Bearing Cages for All Bearing Types

We manufacture solid rolling bearing cages for almost all bearing types – precisely as custom-made parts, as a prototype, or in series. Whether single-row, double-row, split, pin-type, window-type, or comb-type cages:

Our cages are used in industries such as mechanical engineering, wind power, aerospace, and defense technology. Our special designs guarantee maximum precision and durability for every industrial application.

Rolling Bearing

Cages by Bearing

Type for Industry

and Mechanical

Engineering

We manufacture spherical roller bearing cages and barrel roller bearing cages for extreme loads and toughest conditions. From wind turbines to heavy machinery construction, and aerospace, they guarantee maximum stability in heavy-duty operation – even with XXL dimensions.

We manufacture custom solid cylindrical roller bearing cages as custom-made parts – single-row, double-row, as window-type or comb-type cages. Ideal for industrial applications with high loads and precision requirements such as in mechanical engineering and energy technology.

HSP Components manufactures angular contact ball bearing cages according to customer specifications from high-strength steel. These cages are designed for combined axial and radial forces and ensure maximum dimensional accuracy, smooth running, and stability – even at high speeds. Perfect for high-speed applications in industry.

Our deep groove ball bearing cages made of steel or brass are precisely manufactured as custom-made parts. They ensure low friction, high speed resistance, and long service life. They guarantee low-friction operation and high speeds with a long service life.

HSP manufactures four-point contact bearing cages and thrust bearing cages. The solid metal cages are individually designed for high axial forces and compact designs – ideal for energy and plant construction as well as precise drive systems.

For compact bearing designs with high speeds, HSP manufactures needle roller bearing cages from hardened steel or brass. The precise machining ensures maximum dimensional accuracy and smooth running – even with minimal installation space and high loads.

Machining Expertise at a Glance

Manufacturing Processes for

Custom Rolling Bearing Cages

With 4-axis turning, we manufacture rotationally symmetrical parts – even in hardened condition – precisely up to Ø 4,000 mm. Ideal for bearing cages, shafts, and components in tool and mold making. Even with high-strength materials like Inconel or titanium, we impress with dimensional accuracy and process stability.

With 5-axis machining, we realize highly complex milled metal parts – from delicate structures to XXL components (up to 4,500 x 4,500 x 1,500 mm). Thanks to HSC and hard milling, we efficiently process even hardened materials – also for tool and mold making.

Our patented flow forming process replaces classic forming techniques – entirely without a die. The result: up to 80% less material usage with consistent quality. Ideal for large rotationally symmetrical components in medium series. Resource- and CO₂-saving.

We mill gear teeth on rotationally symmetrical components with outer diameters up to Ø 4,000 mm. Ideal for large gearboxes, couplings, or special solutions in drive technology and rolling bearing technology.

With Selective Laser Melting (SLM), we quickly manufacture prototypes and series parts with complex geometries – ideal when conventional methods reach their limits. Also suitable for tool and mold making, e.g., for internal structures or conformal cooling.

Our manufacturing continues to evolve: Soon, 5-axis laser cutting will complement our portfolio – for the precise, efficient, and geometry-independent processing of complex 3D components.

Engineering & Manufacturing Expertise

From Design to Series Production – Your Partner for Custom-Made Rolling Bearing Cages

As a specialist for technical custom-made parts, we manufacture rolling bearing cages precisely according to your specifications – from single pieces to series production. We master difficult-to-machine materials, complex contours, and safety-critical components with test documentation. Our processes enable special sizes from XXS to XXL (up to 4000 mm Ø), complex geometries, and difficult-to-machine materials – from single pieces to series. Certified processes, comprehensive documentation, and individual consultation guarantee maximum quality with optimal cost-effectiveness. Through our deeply integrated processes, modern manufacturing technologies, and high batch size flexibility, we deliver reliably – from prototype to series.

WHY HSP?

Rolling Bearing Solutions That Redefine What Is Technically Feasible

HSP Components utilizes a wide range of innovative and partially patented manufacturing technologies to produce rolling bearing cages precisely as custom-made parts. This allows us to offer the optimal solution for every requirement.

We also reliably and precisely manufacture large-dimensioned rolling bearing cages – . We also implement complex and delicate geometries precisely and economically. Regardless of the dimension – quality and dimensional accuracy are always our focus.

Whether single piece, small series, or large series: HSP flexibly adapts production to your needs, thus ensuring short delivery times and economic production. With digitized production planning, modular processes, and high vertical integration, we flexibly scale our manufacturing for your requirements.

For safety-critical applications, rely on our expertise: HSP produces rolling bearing cages according to the highest safety and quality standards.

All manufacturing steps are fully documented and meet certified testing processes. Thus, your rolling bearing cages meet all industry standards in a traceable and auditable manner.

Our experts advise you on design and optimize your rolling bearing cages for durability, efficiency, and manufacturability.

For seamless integration into your processes, HSP offers tailor-made logistics solutions, from just-in-time deliveries to customer-specific packaging concepts. This way, you receive your ready to mount components precisely at the right time and place in your production process.

Upon request, we take over complete process chains: From procurement to manufacturing to delivery – HSP as your reliable partner for efficient value creation.

We can professionally recondition old or worn rolling bearing cages to save costs and utilize resources sustainably – with HSP Refurbishment Services.

Benefit from our many years of expertise in rolling bearing technology: HSP offers consulting, manufacturing, and optimization from a single source – competent, experienced, and reliable.

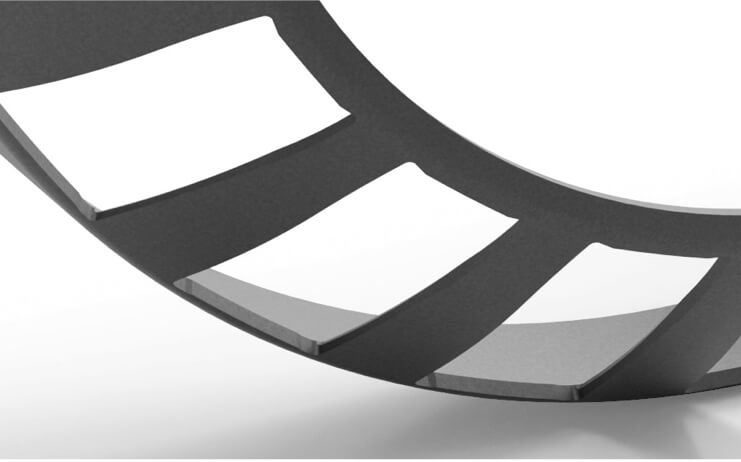

Work Samples of Our Manufacturing Expertise

Custom Rolling Bearing Cages – Large, Delicate Precision Parts as Custom-Made Parts

For decades, HSP has been manufacturing tailor-made rolling bearing cages in exceptional dimensions – from particularly large diameters to delicate, complex geometries. Our expertise includes individual web and window geometries, a wide variety of materials, and precise manufacturing processes, adapted to the requirements of your application. Our projects are generally confidential. Nevertheless, we would like to give you an

insight into our manufacturing expertise. The work samples shown here have been anonymized for reasons of discretion. They exemplify our capability in processing complex geometries, fine surfaces, and difficult-to-machine materials – from single-piece production to series production.

For decades, HSP has been manufacturing tailor-made rolling bearing cages in exceptional dimensions – from particularly large diameters to delicate, complex geometries. Our expertise includes individual web and window geometries, a wide variety of materials, and precise manufacturing processes, adapted to the requirements of your application. Our projects are generally confidential. Nevertheless, we would like to give you an

insight into our manufacturing expertise. The work samples shown here have been anonymized for reasons of discretion. They exemplify our capability in processing complex geometries, fine surfaces, and difficult-to-machine materials – from single-piece production to series production.

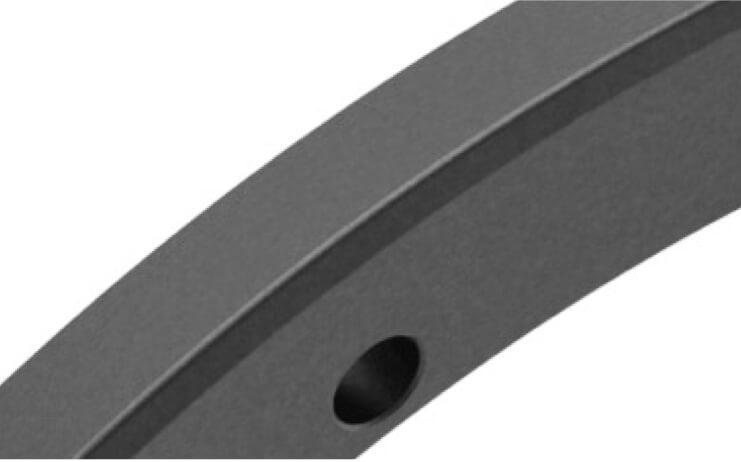

Thrust Bearing Cage Drawing part

Challenge: This large bearing cage, which cannot be produced by conventional forming processes, had to be manufactured by machining as an alternative, even though the thin wall thickness led to instabilities.

Solution: By means of special clamping and tooling techniques, the form geometry could be perfectly produced and brought into series production.

Dimension | Material | Manufacturing Process |

|

|

|

Thrust Bearing Cage Drawing part

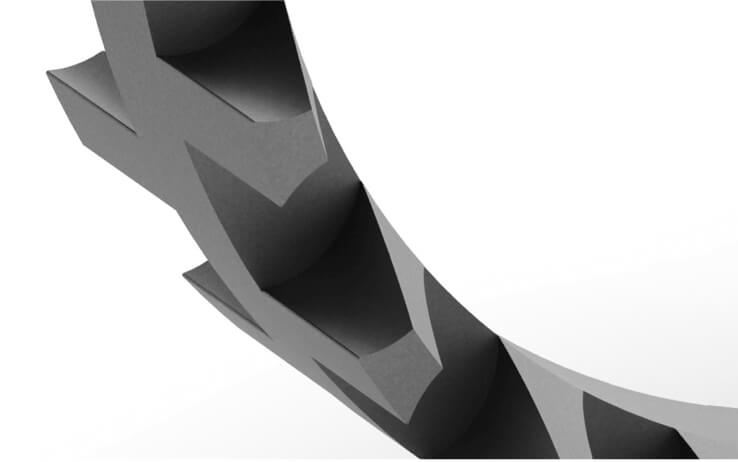

Cage Discs with 100% Alignment Drawing part

Challenge: These very delicate, angled cages must be drilled and milled in such a way that the respective bolt circles are 100% aligned with each other, as they are connected to each other by ground pins.

Solution: With our own clamping technologies and experienced manufacturing personnel, HSP avoids misalignment and ensures precision during assembly – even with complex, split rolling bearing rings.

Dimension | Material | Manufacturing Process |

|

|

|

Cage Discs with 100% Alignment Drawing part

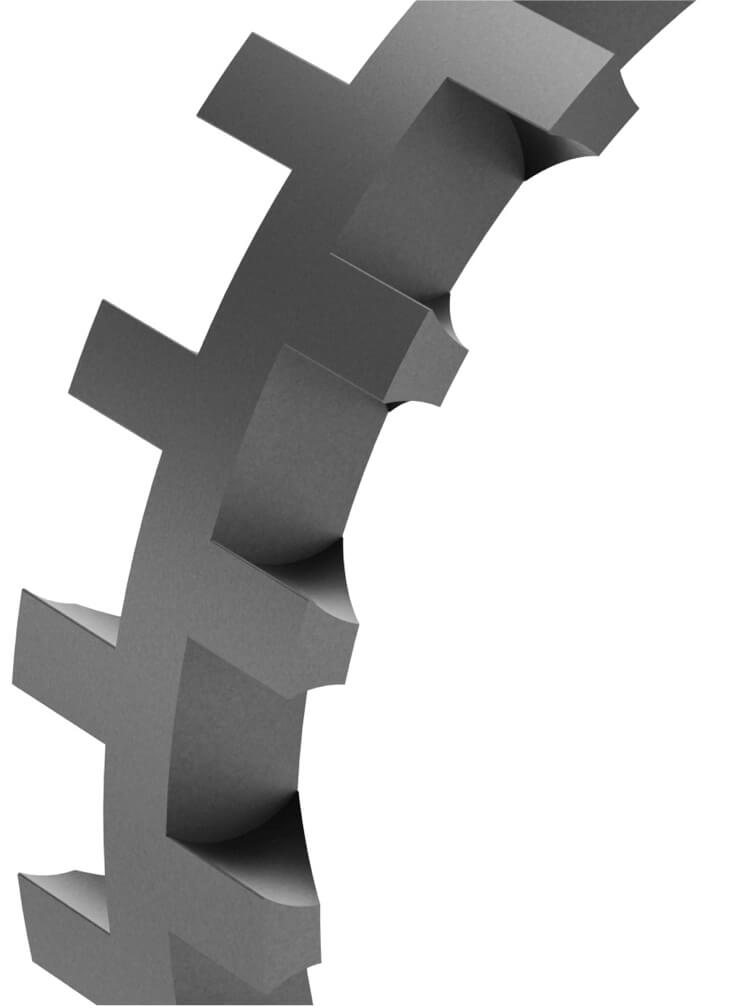

Cylindrical Roller Bearing Cage Drawing part

Challenge: Cylindrical roller cage with precisely aligned pocket rows for reversal. For the steel version, the complex geometries require machine-controlled deburring.

Solution: Through the use of specially programmed machining strategies and automated deburring systems, we ensure consistently high precision, even in series production.

Dimension | Material | Manufacturing Process |

|

|

|

Cylindrical Roller Bearing Cage Drawing part

Custom Manufacturing Services

Safety-Critical Components. Demanding Geometries. Reliable Implementation.

Would you like to learn more about our services for custom-made rolling bearing cages?

Discover our comprehensive services for special designs – from feasibility analysis to just-in-time delivery of ready to mount precision components.