Services for

custom-made parts

and custom-made parts

Whether it’s support with material selection, component optimization, prototyping, manufacturing or assembly: Our services for custom-made parts are as individual as your requirements.

All-round service for industrial companies

From raw material procurement to the Ready to mount assembly – we deliver End-to-End solutions

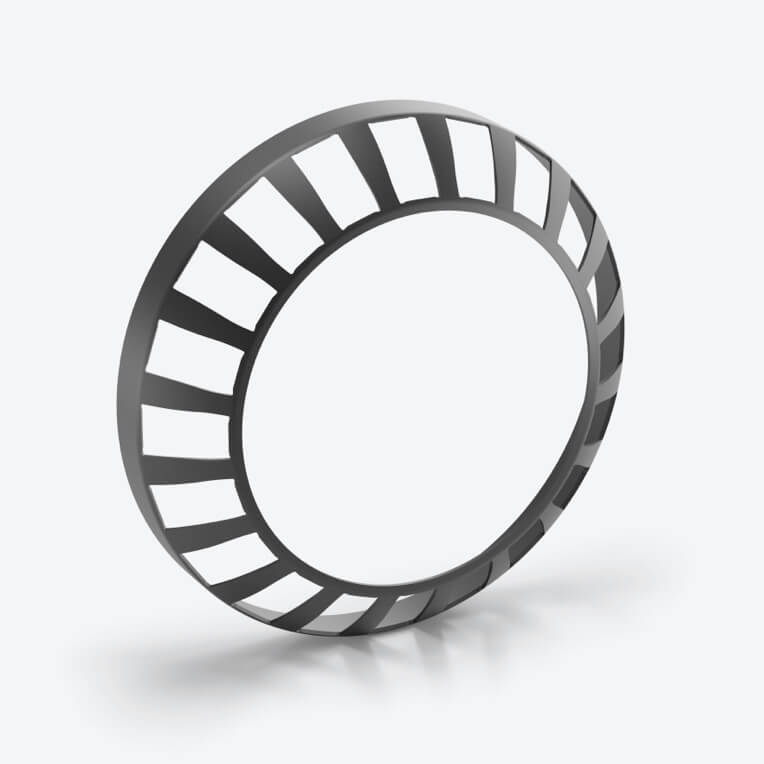

From the first CAD file to the Ready to mount component, HSP accompanies you through the entire development process. Our project services combine engineering, manufacturing and quality assurance into a seamless process

– for individual custom-made parts and rolling bearing cages according to customer specifications. On request, we can take over complete process chains: from material procurement and high-precision manufacturing to assembly and surface treatment, through to logistics and reconditioning. With flexible capacity expansion, worldwide delivery and just-in-time production, we adapt exactly to your project requirements. Whether individual part production, series production or time-critical major project – you benefit from the shortest reaction times, maximum adherence to schedules and smooth processes.

From the first CAD file to the Ready to mount component, HSP accompanies you through the entire development process. Our project services combine engineering, manufacturing and quality assurance into a seamless process

– for individual custom-made parts and rolling bearing cages according to customer specifications. On request, we can take over complete process chains: from material procurement and high-precision manufacturing to assembly and surface treatment, through to logistics and reconditioning. With flexible capacity expansion, worldwide delivery and just-in-time production, we adapt exactly to your project requirements. Whether individual part production, series production or time-critical major project – you benefit from the shortest reaction times, maximum adherence to schedules and smooth processes.

Our services along

the process chain

We think beyond pure manufacturing and relieve you along the entire process chain – with Ready to mount components, on-time delivery and holistic service.

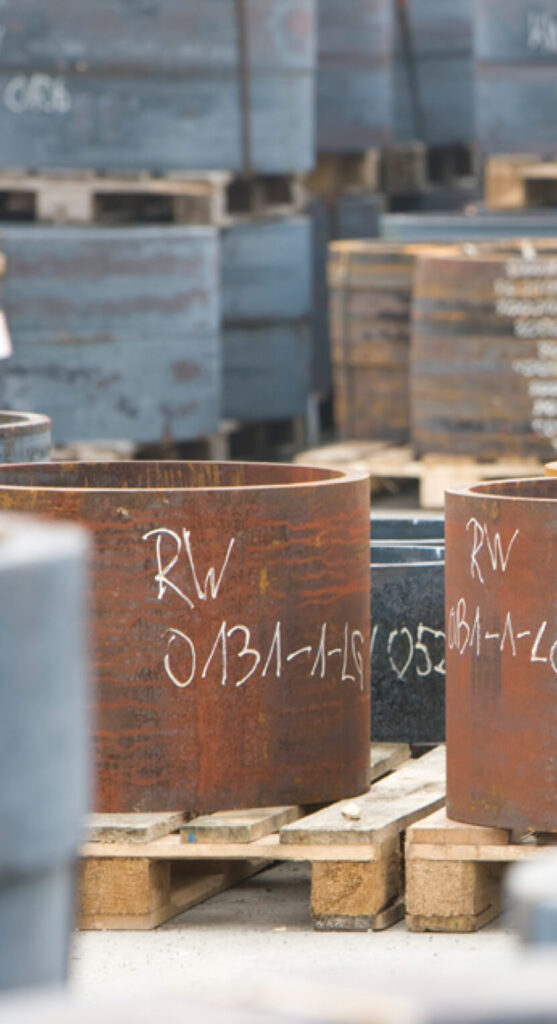

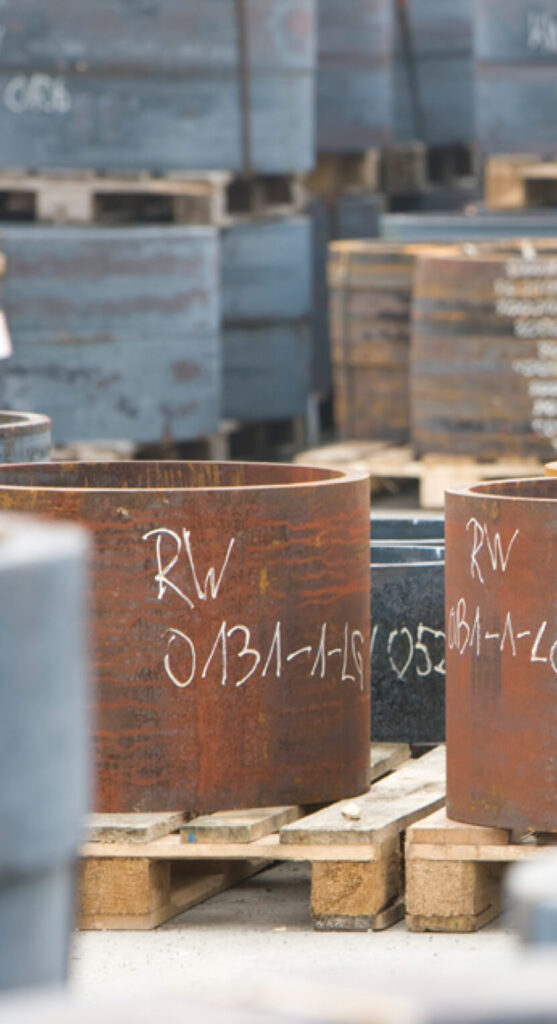

Reliable raw material supply for your custom-made parts:

We procure materials precisely according to technical and economic requirements – including high-performance materials, special grades or certified qualities. This saves you interfaces and ensures smooth project processing.

Turning, milling, flow forming, 3D printing – precisely from a single source:

With our broad manufacturing expertise, we realize components in series or special sizes. We also manufacture complex geometries, difficult-to-machine materials or filigree details in-house – efficiently, precisely and on schedule.

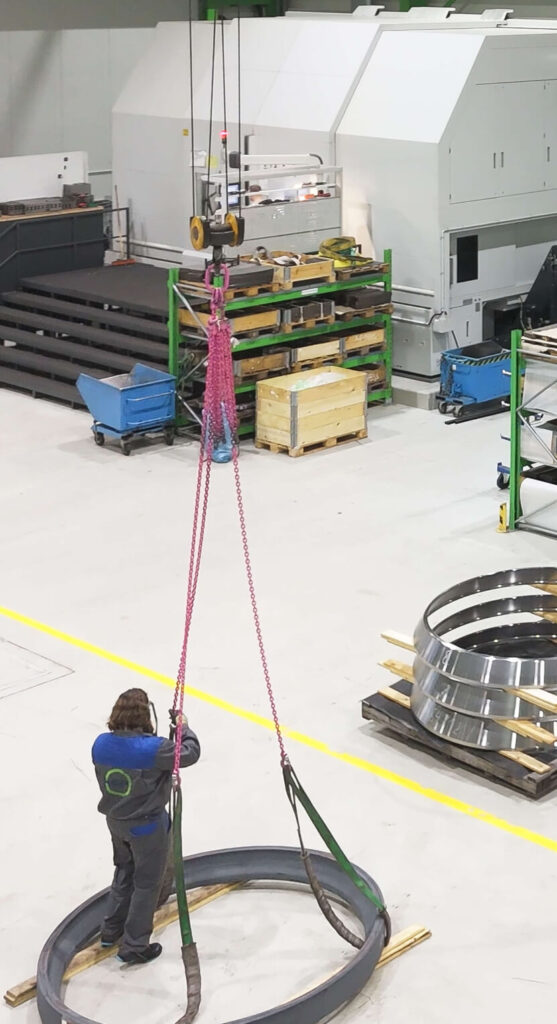

Ready to mount assemblies – mechanically or electromechanically pre-assembled:

We assemble your components into complete assemblies – including testing processes, functional control and documentation. Whether mechanical or electromechanical systems: You receive Ready to mount units, directly for installation.

Quality assurance as a process-accompanying standard:

Industry 4.0 starts digitally and ends digitally. Our QA supports test planning, implementation and documentation on 3D models and an internal CAQ system, so that transparent traceability and process reliability can be proven in every process step.

Individual logistics solutions for your supply chain

From call-off warehouse to packaging to just-in-time delivery: We adapt to your logistics processes – nationally and internationally.

Professional reconditioning of your custom-made parts:

Sometimes, due to wear or external influences such as damage to very valuable components, the question arises: “Can this still be saved?” If requested, we will check the technical feasibility in these cases to assess whether reconditioning is possible and economical, and repair your custom-made parts. This helps you save time and money while conserving natural resources.

From the idea to the component

Custom-made parts – precisely manufactured according to drawings

Whether complex prototypes or near-series custom-made parts – HSP realizes precision parts up to a size of 4,000mm outer diameter exactly according to customer specifications. Our many years of experience in the production of custom-made parts guarantees maximum dimensional accuracy, process-reliable processes and documented quality – from CAD data checking to final inspection.

Complete solutions for OEM

Additional services around your custom-made parts

As an OEM or manufacturer, you benefit at HSP not only from

high-precision custom-made parts and custom-made parts,

but also from tailor-made services along the entire process chain. We support you with technical advice, material and process selection, individual logistics and flexible capacities – for Ready to mount components with maximum process reliability and adherence to schedules.

WHY HSP?

Ready to mount components from a single source –

Your advantages with HSP as a manufacturing partner

HSP takes over not only the manufacturing for you, but also upstream and downstream processes. From material procurement to Ready to mount delivery, you save time, interfaces and costs.

You receive Ready to mount components that can be integrated directly into your production line. This avoids rework, reduces the effort in final assembly and increases your efficiency.

Thanks to state-of-the-art measuring technology and strict testing procedures, we guarantee maximum dimensional accuracy. Your custom-made parts meet all norms and industry-specific standards.

Whether individual part, small series or series production – HSP manufactures exactly according to your needs. This allows you to remain flexible and avoid unnecessary storage costs.

Our experts support you already in the development phase with feasibility studies and design optimization. This results in solutions that are technically feasible, economically sensible and future-proof.

With HSP, you have a partner that acts directly and uncomplicatedly. Fast coordination and dynamic processes ensure that your projects are implemented on schedule.

From Just-in-Time to Vendor-Managed-Inventory, we develop tailor-made logistics concepts for you. Your components arrive reliably, neutrally packaged and exactly at the agreed time.

With our refurbishing service, we extend the service life of your components. This conserves resources, reduces costs and supports your sustainability strategy.

At HSP, you benefit from decades of experience in various industries – from rolling bearings to aerospace to medical technology. We understand your requirements and deliver solutions that deliver on their promise.

FAQ about

custom-made

parts, project

process & Services

Custom-Made Parts

Custom-made parts are customer-specific custom-made parts that deviate from DIN standards and are manufactured exactly according to the specifications of a technical drawing or CAD file. They are individually designed and produced to meet specific requirements for geometry, material, tolerance or function.

HSP offers a wide range of processes for custom-made parts. In addition to machining processes such as CNC milling and turning, we also manufacture precision components using 3-D printing. Our patented flow forming is also available for the economical production of high-precision custom-made parts.

Project process

Each custom-made part begins with a feasibility analysis by our experts. We analyze your requirements and advise you on suitable manufacturing processes. We then create a precise drawing and manufacture the part according to your specifications. From prototypes to series production, we accompany you in every phase.

Yes, we offer both sample production and small series. This allows you to test the functionality and quality of your components before you go into series production. We manufacture according to your specifications and ensure that all parts meet the desired specifications.

For our custom-made parts, we use a variety of materials, including steel, stainless steel, aluminum and special alloys. We can also precisely machine difficult-to-machine high-performance materials. We would be happy to advise you on the best material options for your project.

We manufacture custom-made parts in a wide range of sizes, from small, filigree components to larger, heavier components. The maximum dimensions depend on the respective manufacturing process and the machine capacity used. We would be happy to check the feasibility for larger components as well.

Services

Yes, our team offers you comprehensive support in the design and optimization of your components. If desired, we can help you to create your drawings or to optimize them for economical production.

Yes. For custom-made parts and series projects, HSP Components offers tailor-made logistics concepts – from just-in-time delivery to customer-specific packaging and labeling. In this way, we ensure process-reliable integration into your supply chain and shorten the distances between production, assembly and the place of use.