From prototype

construction to serial

production in record time

Case Study Rolling Bearing Industry

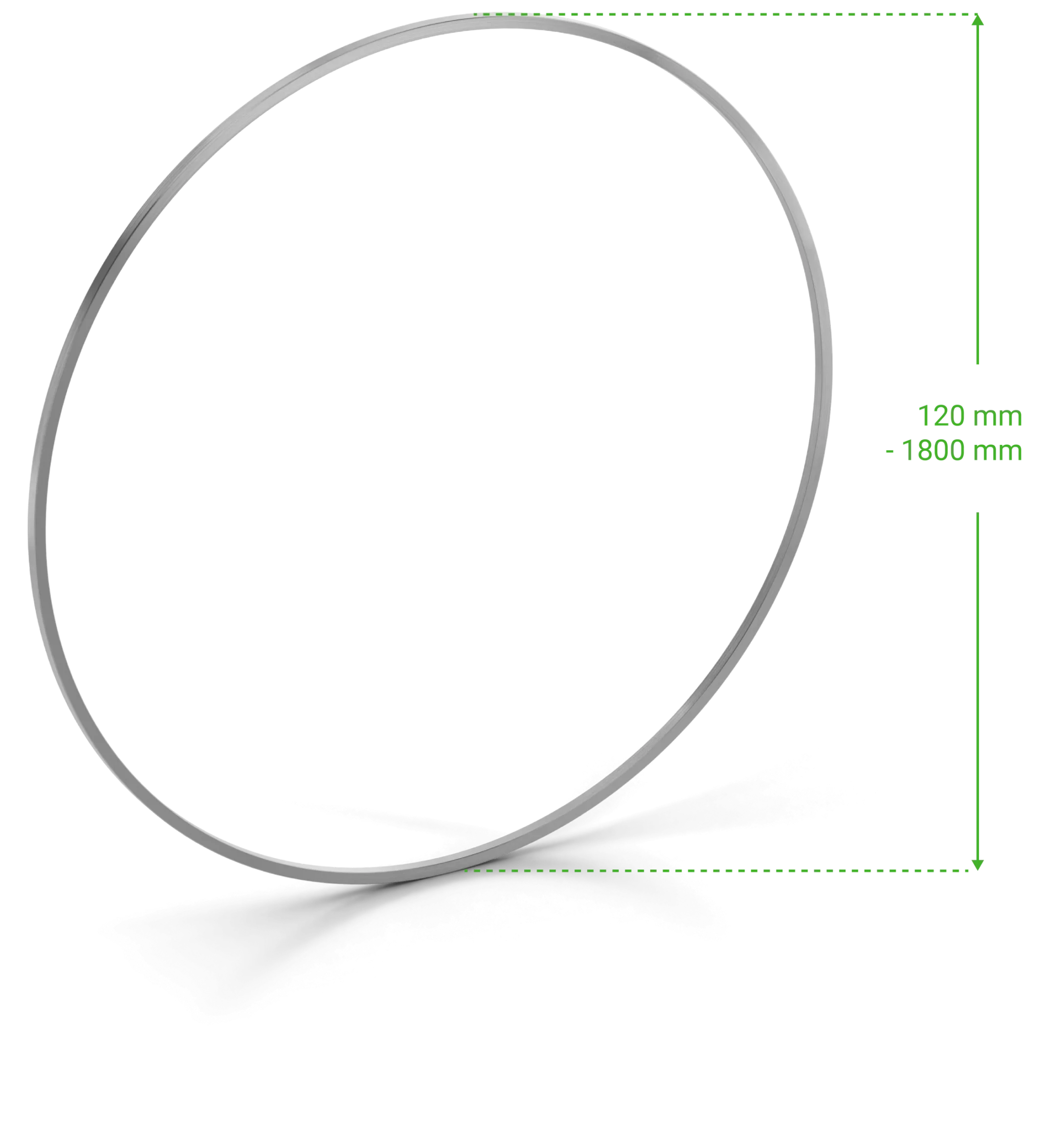

Thin-walled guide ring made of hardened steel for heavy-duty rolling bearings

Guide Ring Drawing part

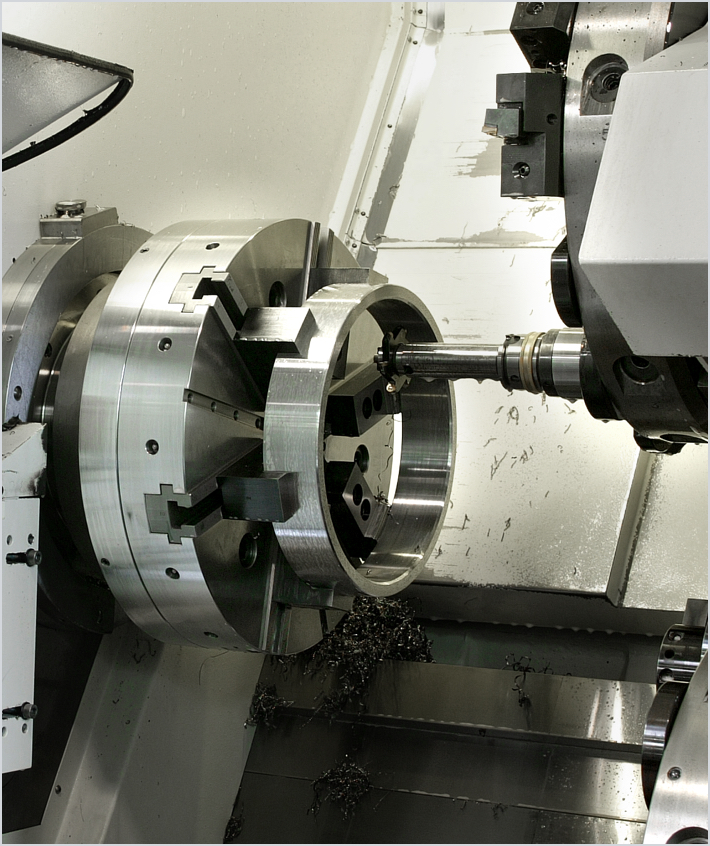

Task: Manufacture of an extremely delicate, axially movable guide ring made of hardened steel for heavy-duty rolling bearings – precisely manufactured in a short time and scalable for several variants.

Solution: Special turned part manufactured with specially developed clamping technology, scaled from zero series to a complete product family within a few months – with maximum precision, high repeatability and perfect integration into series production.

Dimension | Material & Hardness | Tolerances & Quality |

|

|

|

Guide Ring Drawing part

Challenge

Scalable solution for extreme loads: floating guide ring

For an internationally operating company in the rolling bearing industry, HSP was to manufacture a customer-specific turned part made of steel – used as a “floating” guide ring – for guiding cages and rolling elements in heavy-duty, multi-row bearing solutions for industrial applications. The component was structurally designed as part of a new development and should:

- be brought to series production readiness within a very short time and

- be scalable in different variants for a broad product range

Special technical challenges:

- Extremely thin-walled geometry

- Use of hardened steel with a matte surface

- High precision with minimal component thickness

- Time-critical prototype construction with simultaneously high series requirements

For an internationally operating company in the rolling bearing industry, HSP was to manufacture a customer-specific turned part made of steel – used as a “floating” guide ring – for guiding cages and rolling elements in heavy-duty, multi-row bearing solutions for industrial applications. The component was structurally designed as part of a new development and should:

- be brought to series production readiness within a very short time and

- be scalable in different variants for a broad product range

Special technical challenges:

- Extremely thin-walled geometry

- Use of hardened steel with a matte surface

- High precision with minimal component thickness

- Time-critical prototype construction with simultaneously high series requirements

RESULT

Series-produced guide ring through automated production and high precision

A complex individual component became a series-produced, highly functional guide ring – precise, economical and perfectly matched to the requirements of modern rolling bearings. Thanks to automated processes and targeted investments in manufacturing technology, economies of scale could also be used and costs sustainably reduced.

What we have done

Services at a glance: competently supported in every project phase

Thanks to our many years of experience with thin-walled, rotationally symmetrical drawing parts and sophisticated materials, we were able to realize the project with high precision:

- Composition of an overarching project team

- Development and use of a special clamping technology to avoid deformations during turning

- Iterative alignment between design, manufacturing and series transfer

- Agile scaling from the zero series to the complete product family in a short time

The floating guide ring was thus successfully integrated into all series solutions of the customer within a few months.