Professional Dismounting

& Mounting of Rolling

Bearings with Hydraulic

Methods

With the hydraulic method from HSP Components, you offer your customers precise, damage-free, and time-saving rolling bearing mounting – ideal for specialist dealers who want to ensure maximum process reliability for maintenance personnel.

Products with Hydraulic Methods

Longer service life. Less downtime. More precision.

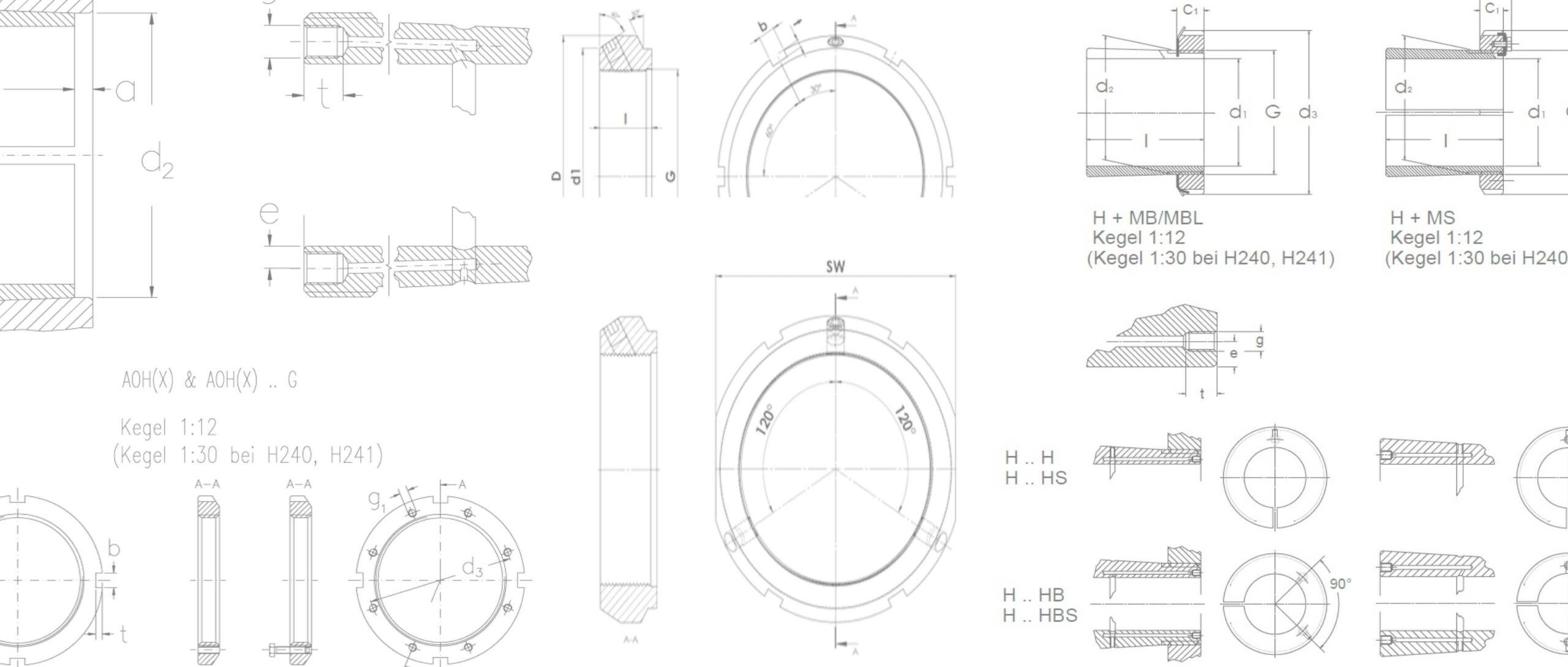

The professional mounting and dismounting of rolling bearings determines the performance and service life of systems. In the hydraulic method, oil is distributed via bores and grooves in the mating surfaces. The resulting oil film creates an even gap between the shaft and bearing and reduces friction. This allows rolling bearings to be mounted or dismounted with precision –

without damaging surfaces and with significantly less effort. Upon request, we supply our components with oil bores and distribution grooves for smooth installation. This way, your customers save assembly effort, protect components, and reduce downtime costs – even for large or difficult-to-handle bearings.

The professional mounting and dismounting of rolling bearings determines the performance and service life of systems. In the hydraulic method, oil is distributed via bores and grooves in the mating surfaces. The resulting oil film creates an even gap between the shaft and bearing and reduces friction. This allows rolling bearings to be mounted or dismounted with precision –

without damaging surfaces and with significantly less effort. Upon request, we supply our components with oil bores and distribution grooves for smooth installation. This way, your customers save assembly effort, protect components, and reduce downtime costs – even for large or difficult-to-handle bearings.

Safety and Efficiency in the Mounting Process

Advantages of Components with

Hydraulic Methods from HSP Components

With HSP’s hydraulic method, rolling bearings can be mounted and dismounted quickly and damage-free – even for large bearings.

Thanks to integrated oil channels, bearings can be precisely aligned and readjusted at any time if required – for maximum process reliability in every application.

The hydraulic system allows for flexible adjustment of bearing clearance directly on site, without complex mechanical rework.

Hydraulic withdrawal sleeves protect the shaft and bearing even under unforeseen loads, preventing costly damage and downtime.

Hydraulic methods offer an economical solution for large or hard-to-reach bearings – without expensive special bores.

We offer hydraulic solutions for various shaft diameters, enabling specialist dealers to provide their customers with precisely fitting solutions.

1:1 compatible with standard market systems and existing OEM products.

Hydraulic methods significantly shorten mounting and dismounting times, minimizing production downtimes.

Due to precise pressure build-up and easy handling, working time, effort, and personnel costs are reduced – a plus for specialist dealers and their end customers.

FAQ – Frequently

Asked Questions

about the

Hydraulic Method

for Rolling Bearing

Mounting

In the hydraulic method, a thin lubricating film is created between the bearing and the shaft using pressurized oil in special oil channels. This allows rolling bearings to be mounted or dismounted in a controlled manner – faster, more precisely, and without damage.

The method prevents bearing damage, reduces mounting times, and increases process reliability. Especially for large bearing diameters, the hydraulic method is significantly more cost-effective, efficient, and durable.

HSP Components offers a coordinated range of adapter and withdrawal sleeves as well as locking elements – all manufactured according to OEM standards and compatible with standard market systems.

Yes, by returning the pressurized oil, bearings can be safely and damage-free released. This protects both shafts and bearing seats and saves time during maintenance.

Our experts will advise you individually on suitable components, oil channel designs, and mounting aids. Use our product service or contact us directly.