HSP Schwahlen 118 days ago

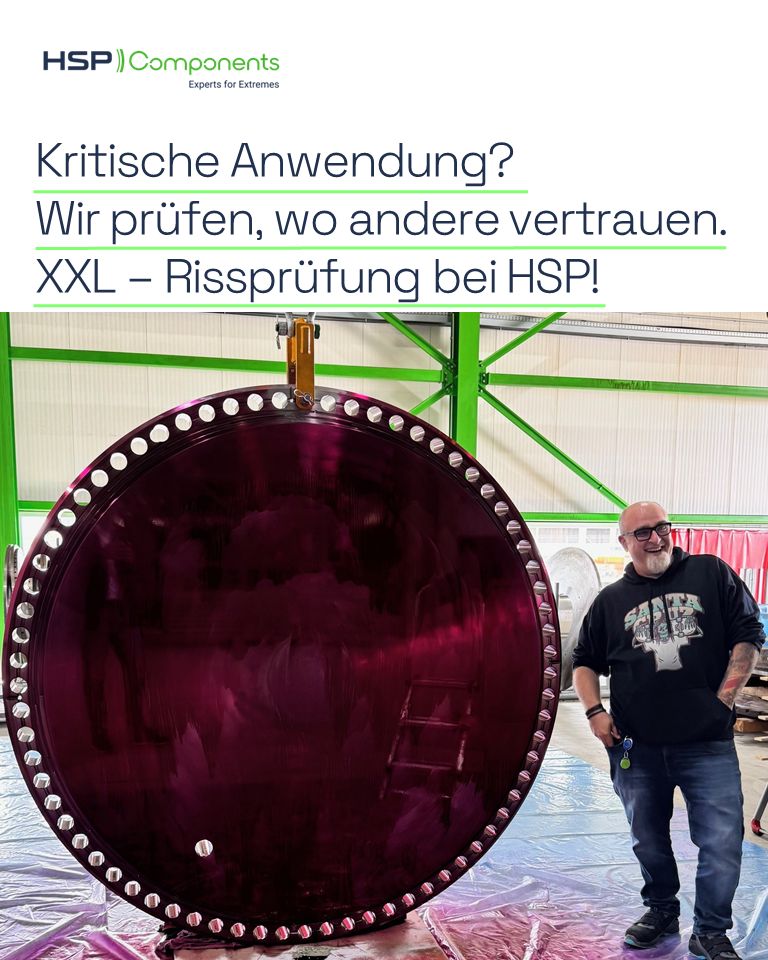

🔍 Wir prüfen, wo andere vertrauen. XXL – Rissprüfung bei HSP! Wenn

…more

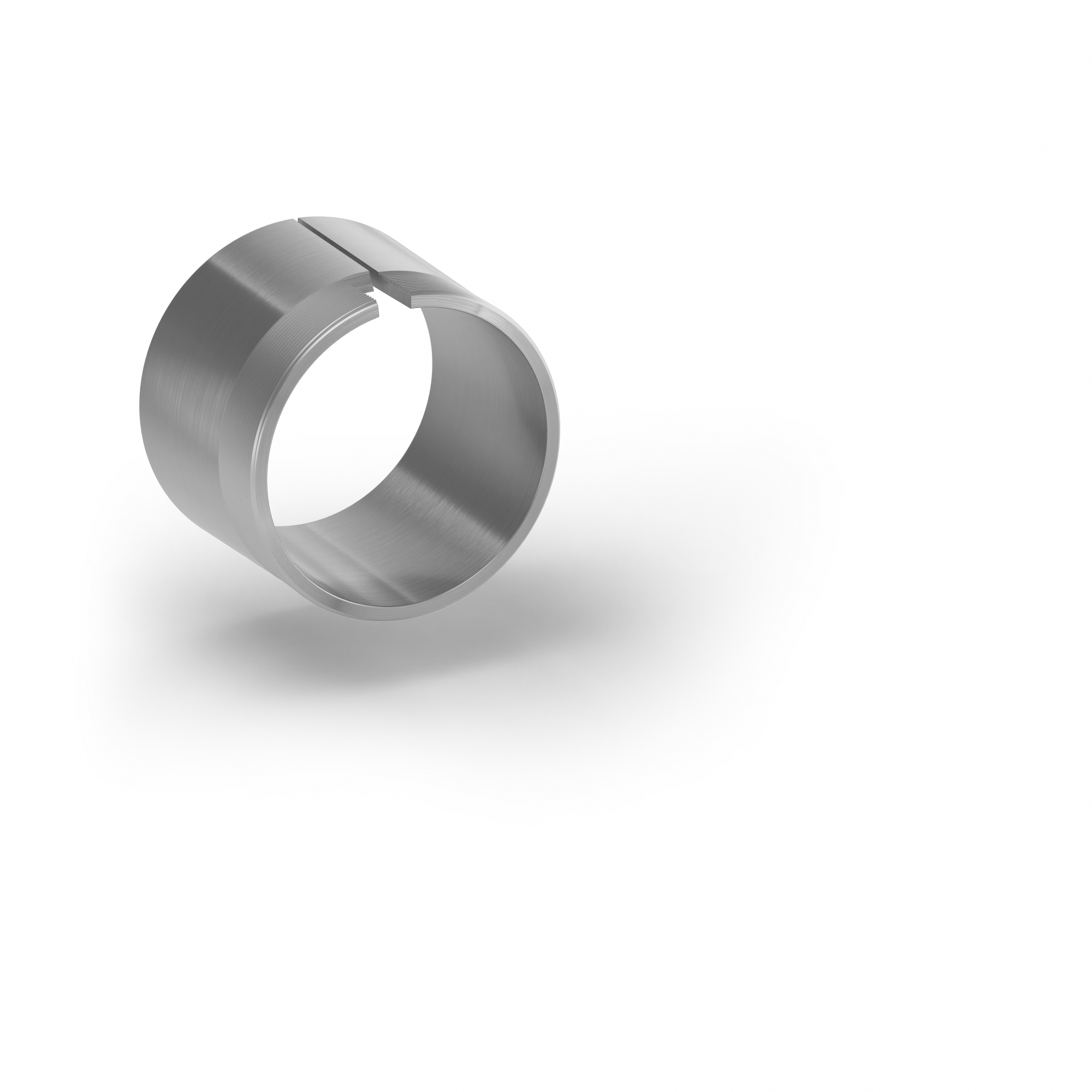

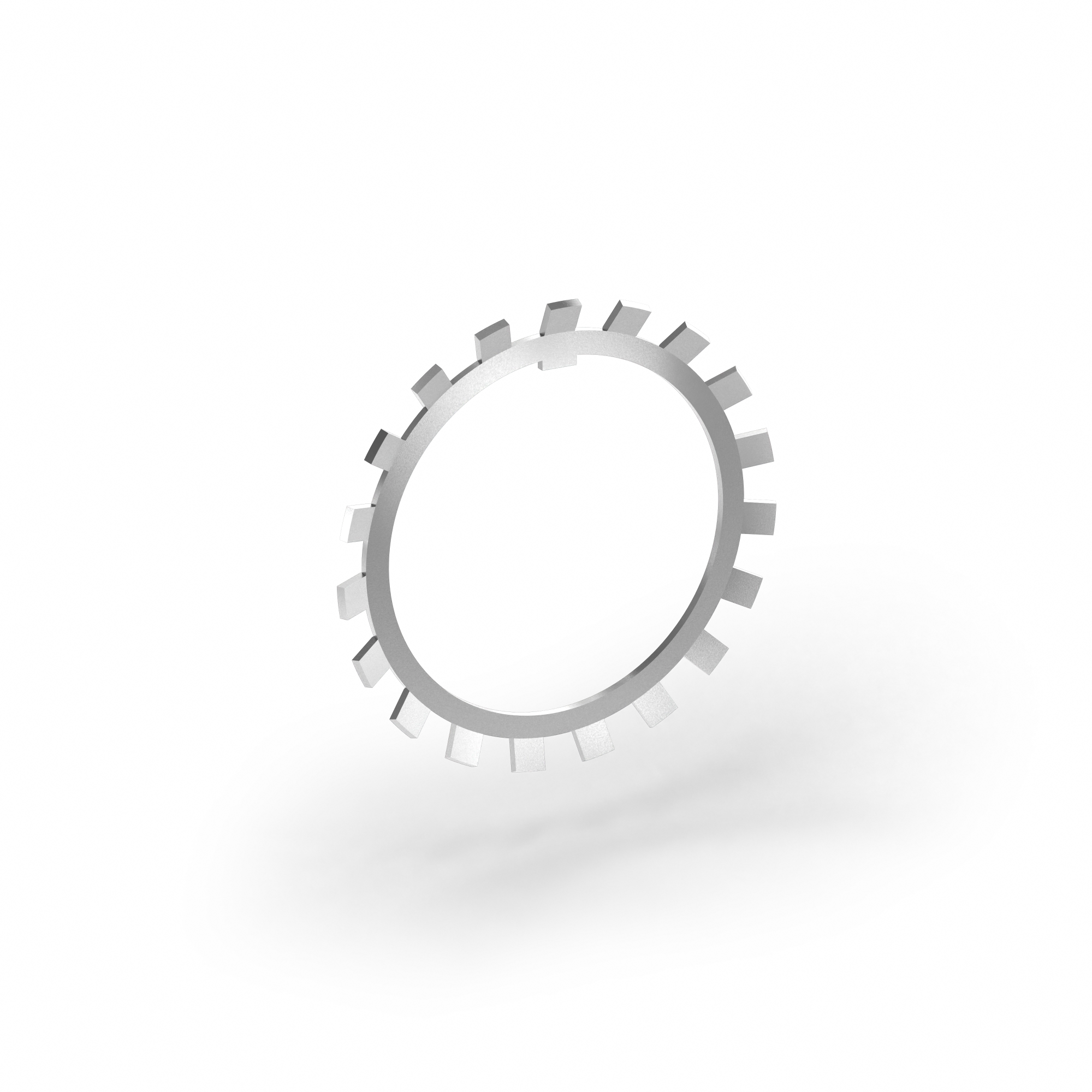

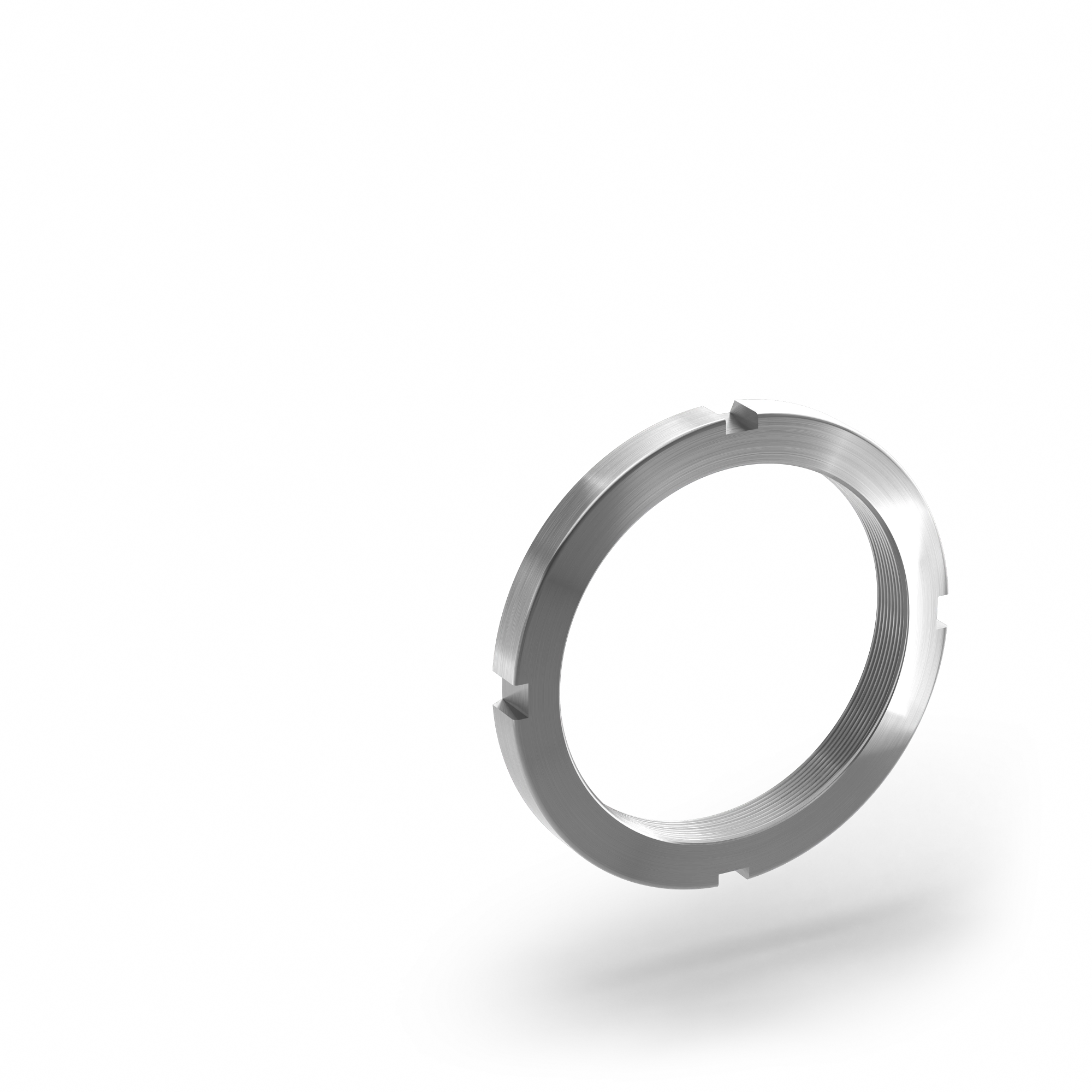

Ready-to-assemble precision parts & bearings components for OEM & after-sales. Discover standard parts for your product range or customized special designs according to drawings.

WHO WE ARE: EXPERTS FOR EXTREMES

As a technology partner for industry and trade, HSP Schwahlen GmbH develops and produces ready-to-assemble precision components. The company combines two business areas under the brand name HSP Components: OEM-quality bearings components for the technical

trade and custom-made parts for industry.

Whether standard products or custom-made products – HSP delivers ready-to-install solutions exactly where and when they are needed. To achieve this, we are rethinking manufacturing: with digitalized processes, comprehensive manufacturing expertise and individual advice, we deliver maximum precision with maximum efficiency. Optimized processes thus shorten our customers’ time-to-market.We specialize in extreme challenges: Whether manufacturing large parts, complex geometries or difficult-to-machine materials – where others give up, we are in our element. As a technology partner for demanding industries and applications, we supply ready-to-install precision components in series – reliably, on time, worldwide.

As a technology partner for industry and trade, we offer tailor-made solutions that are characterized by precision, process reliability and delivery reliability – in series production or small batches, in Europe and worldwide.

Our modern metal processing combines digital processes, broad vertical integration and individual consulting – for your efficiency and time-to-market.

As a technology partner for industry and trade, HSP Schwahlen GmbH develops and produces ready-to-assemble precision components. The company combines two business areas under the brand name HSP Components: OEM-quality bearings components for the technical

trade and custom-made parts for industry.

Whether standard products or custom-made products – HSP delivers ready-to-install solutions exactly where and when they are needed. To achieve this, we are rethinking manufacturing: with digitalized processes, comprehensive manufacturing expertise and individual advice, we deliver maximum precision with maximum efficiency. Optimized processes thus shorten our customers’ time-to-market.We specialize in extreme challenges: Whether manufacturing large parts, complex geometries or difficult-to-machine materials – where others give up, we are in our element. As a technology partner for demanding industries and applications, we supply ready-to-install precision components in series – reliably, on time, worldwide.

As a technology partner for industry and trade, we offer tailor-made solutions that are characterized by precision, process reliability and delivery reliability – in series production or small batches, in Europe and worldwide.

Our modern metal processing combines digital processes, broad vertical integration and individual consulting – for your efficiency and time-to-market.

WHY HSP?

HSP has been established in the demanding rolling bearing market for decades and brings in-depth technological expertise to every customer solution.

Tightest H6 tolerances for roundness, flatness and diameters as well as wall thickness variations in the y-range ensure maximum precision for highly stressed applications.

Our own clamping and manufacturing processes, some of which are patented, enable economical and precise production even under extreme conditions.

Whether hardened steel, titanium or nickel-based alloys – HSP masters even difficult-to-machine materials with maximum precision.

Whether XXS or XXL components: HSP manufactures highly precise components in every dimension and geometry in series. Economical and process-reliable.

With scanning 3D measuring technology and air-conditioned production facilities, HSP specialists guarantee maximum precision and consistent quality.

ERP, DMS and CAQ ensure seamless documentation and efficient connection – including AI and web EDI interfaces.

HSP is audited and certified in accordance with ISO 9001 and 14001 and many customer-specific systems – we can also implement additional quality specifications for your project on request.

Custom-made products, series products or just-in-time delivery – HSP adapts to your processes and requirements, not the other way around.